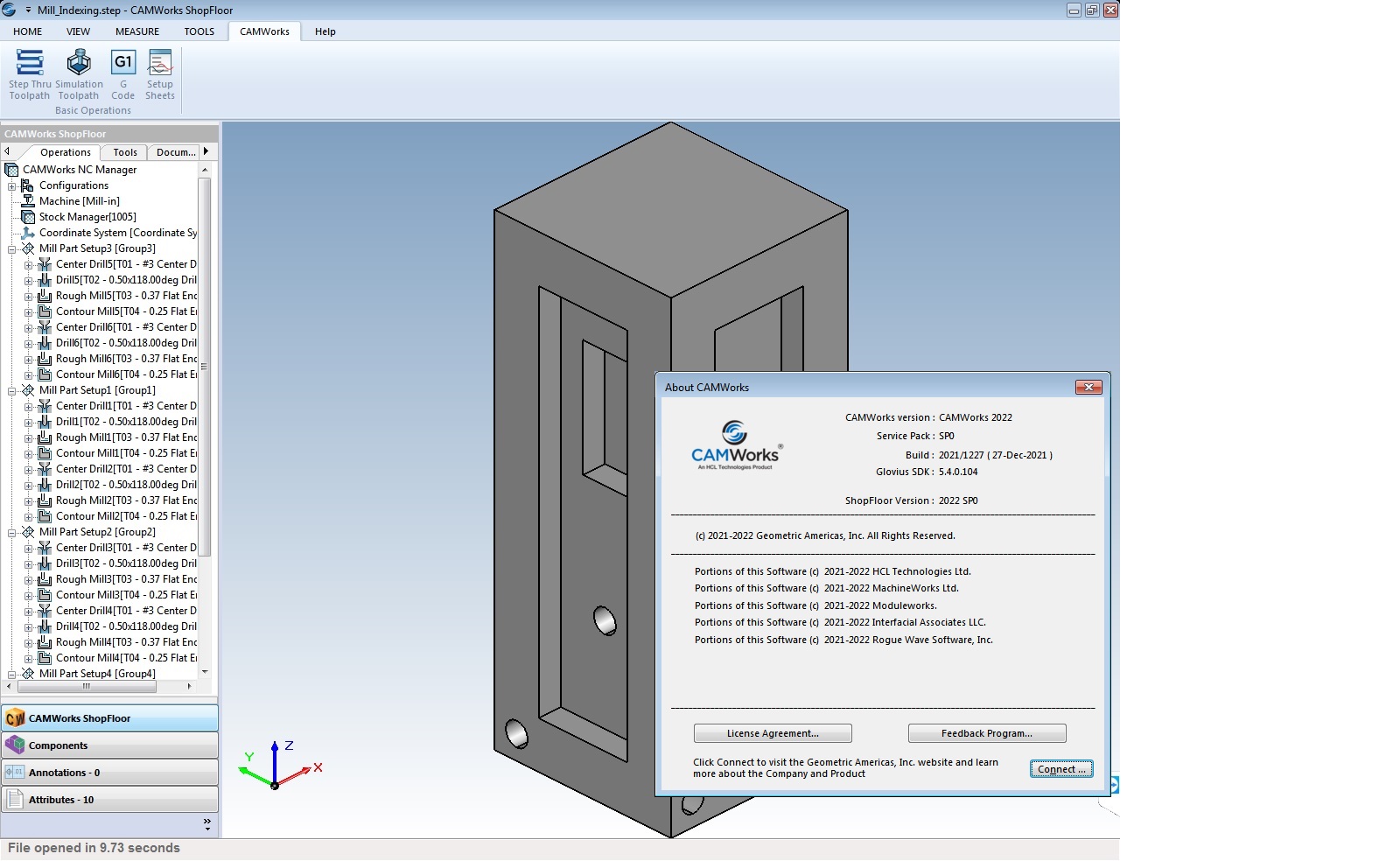

Download CAMWorks 2022 SP0 Multilang for SolidWorks 2021-2022 x64 full

Link download CAMWorks 2022 SP0 Multilang for SolidWorks 2021-2022 win64

Working with CAMWorks 2022 SP0 full

Description: CAM (Computer Aided Manufacturing) Works – a module for creating control programs for CNC machines.

Programming of milling, turning, turning-milling and wire erosion machining by means of the CAMWorks module.

* The CAMWorks module allows you to create programs for milling, turning, turning-milling and wire erosion machining. The following machine types are supported: Milling machines with simultaneous control of two? five axles;

* Turning one- and two-spindle, with one or two calipers, with software-controlled auxiliary mechanisms (tailstock, lunettes, catchers of parts …);

* Turning and milling one- and two-spindle, with one or two calipers, with software-controlled auxiliary mechanisms, with simultaneous control of two to five axes;

* Erosional two- and four-axis.

Processing is carried out directly in the SolidWorks environment and directly on the SolidWorks model. The results of the programmer’s work are saved in the same model of the SolidWorks part or assembly. This ensures complete associativity of the model and tool paths, which leads to an automatic update of all tool paths when making changes to the model. When adding any technological data to the SolidWorks model, such as roughness designations, datums, tolerances of the shape and location of surfaces, dimensional tolerances, the programmer always has direct access to them, which makes it easier to select the layout of the part on the machine and the selection of the necessary ensuring the specified quality of the tool part and cutting conditions. The part can be easily adapted to the needs of machining by, for example, eliminating geometry elements that are unnecessary in terms of machining or by recalculating the executive dimensions of the model to the middle of the tolerance range. In the SolidWorks assembly mode, you can perform joint processing of several parts, program the processing of a series of parts, or simply completely simulate the entire real situation on the machine table – all tooling, a workpiece of any complexity, and so on – for the most complete consideration of the realities of processing already at the earliest stages creating a program.

If you want to download CAMWorks 2022 SP0 full license, please click to DOWNLOAD symbol and complete check out a little help my website is maintained. The download link is appeared automatically when you complete check out.

Please see youtube video for download instruction by open *.txt file and copy youtube video link paste to your browser If you don’t know how to download.

Inside folder CAMWorks 2022 SP0, already have crack’s file and instruction how to install CAMWorks 2022 SP0 step by step. I guarantee you can install CAMWorks 2022 SP0 successfully if you follow that instruction.

If you also can not install it or any problems, please contact to me by email: clickdown.org@gmail.com, then I will help you to install software by teamviewer.

Thanks a lot