Download ASDIP Foundation 5.0.0.1 full license forever

Link download ASDIP Foundation 5.0.0.1 full cracked

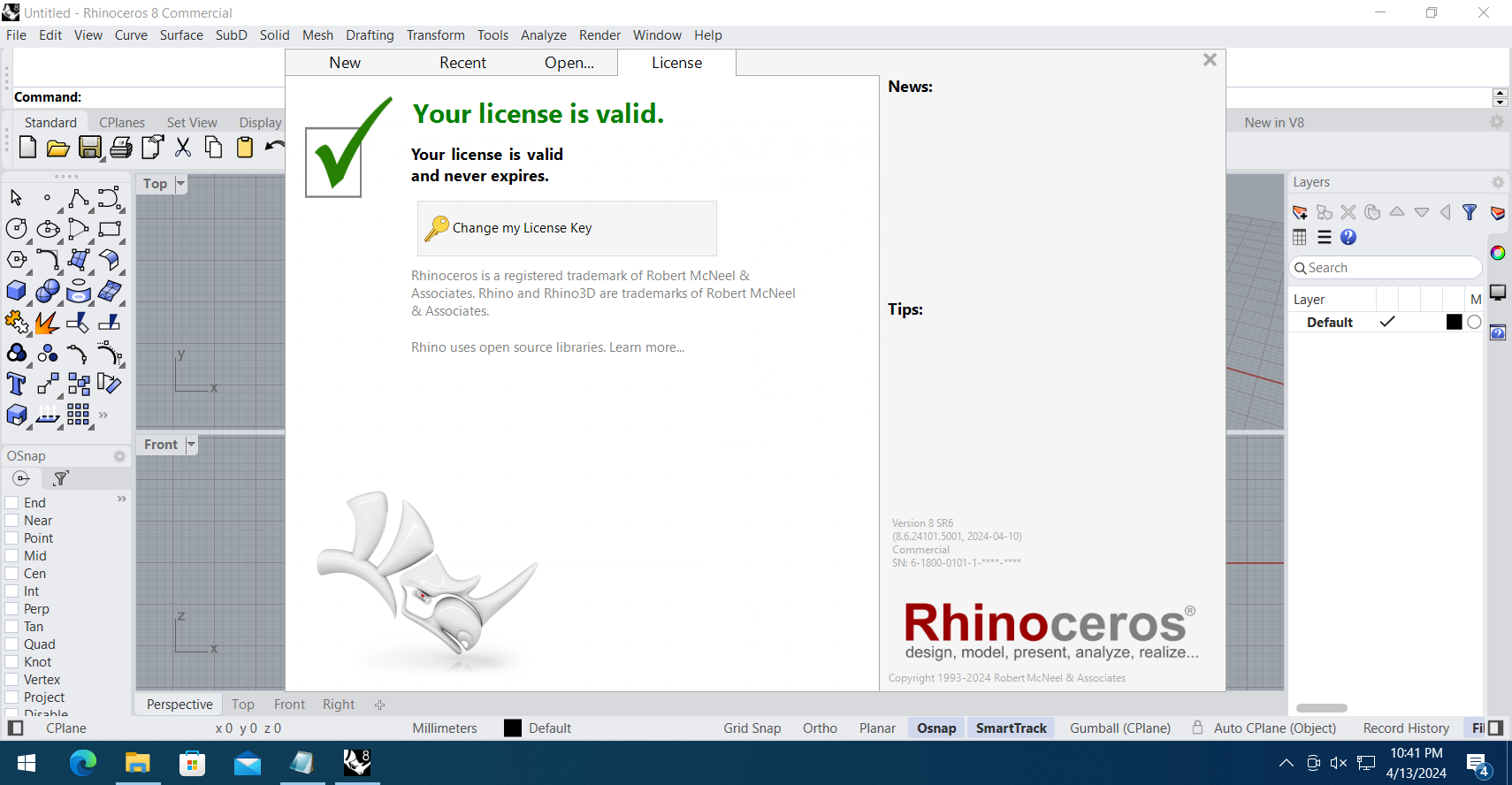

Working with ASDIP Foundation 5.0.0.1 full license

Description of ASDIP Foundation 5.0.0.1

It is a powerful software tool designed specifically for structural engineers. Its primary purpose is simplifying and accelerating the often time-consuming process of calculating and designing pile caps and concrete footings. This software is a game-changer for professionals in the field, offering numerous benefits that enhance productivity and accuracy.

Key Benefits of ASDIP Foundation 5.0.0.1

Efficient Modeling: One of the standout features of the software is its user-friendly graphical interface, allowing engineers to model concrete footings easily. This intuitive approach saves valuable time and ensures that your designs are accurate.

Code Compliance: With this tool, you can confidently optimize your designs while adhering to the latest design code provisions, including ACI 318 and CSA A23.3. This ensures that your projects meet the highest structural standards.

Professional Reports: Impress your clients and plan-checkers with professional reports generated by the software. These reports can be condensed or detailed, providing all the necessary information in a clear and organized manner.

Extensive Support: It offers extensive documentation, including solved examples and blog posts that guide you through the software. This support ensures that you can make the most of the software’s capabilities.

Efficient Data Management: The software allows you to create, organize, manage, and securely store your electronic calculations. This feature simplifies the workflow and ensures that your data is readily accessible when needed.

If you want to download ASDIP Foundation 5.0.0.1 full license, please click to DOWNLOAD symbol and complete check out a little help my website is maintained. The download link is appeared automatically when you complete check out.

Please see youtube video for download instruction by open *.txt file and copy youtube video link paste to your browser If you don’t know how to download.

Inside folder ASDIP Foundation 5.0.0.1, already have crack’s file and instruction how to install ASDIP Foundation 5.0.0.1 step by step. I guarantee you can install ASDIP Foundation 5.0.0.1 successfully if you follow that instruction.

If you also can not install it or any problems, please contact to me by email: clickdown.org@gmail.com, then I will help you to install software by teamviewer.

Thanks a lot