download Siemens Tecnomatix 8.0 Suite for CATIAV5-IDEAS-NX-ProE x86 x64

Link download Siemens Tecnomatix 8.0 Suite for CATIAV5-IDEAS-NX-ProE x86 x64 full

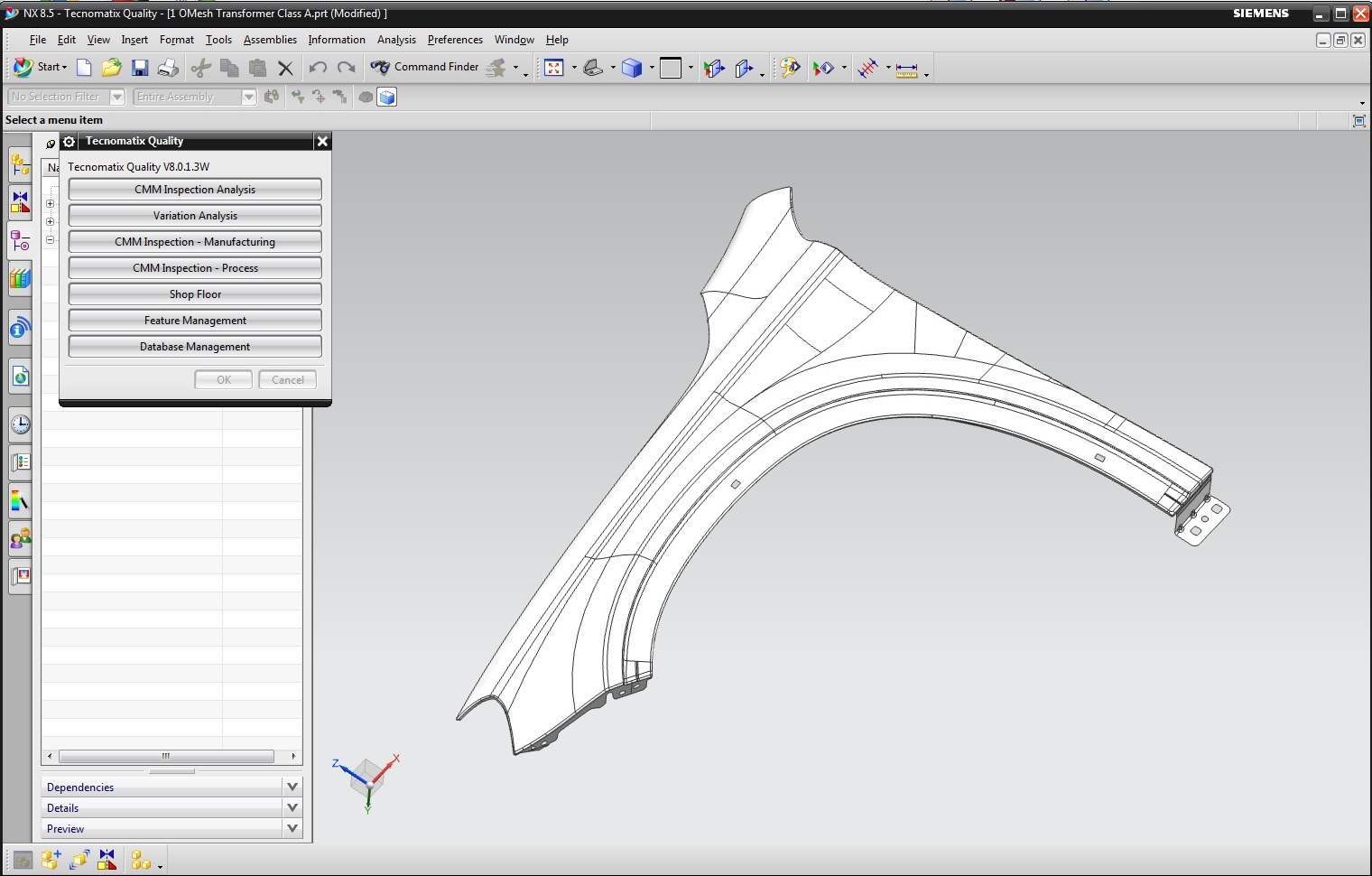

Siemens Tecnomatix 8.0 Suite for CATIAV5-IDEAS-NX-ProE x86 x64

Siemens Tecnomatix 8.0 Suite for NX 8.5 full license

Tecnomatix Quality is a family of software products designed to analyze dimensional deviations, exchange information about product quality, create control programs for coordinate measuring machines (CMM) and CNC machines based on the CAD model.

The Tecnomatix Quality Management applications support the concepts of lean manufacturing and six sigma. The digital environment allows you to model the assembly of a product from deviated parts, identify problems and the most critical tolerances, thus eliminating possible difficulties in assembly due to the variation in size.

Reducing the deviations of the assembled product is based on the Dimensional Planning & Validation (DPV) dimensional analysis tool, which predicts the magnitude and causes of variation during the process. Using this tool, engineers create a three-dimensional digital prototype for a complete simulation of the production process, including modeling the tolerances and errors of parts during processing. Using DPV, you can capture large volumes of real parts that are performed in the measurement shops and manage them in the Teamcenter environment. Designers and technologists can apply search and analysis functions to compare data on the quality of products manufactured at different plants and optimize products and production processes. This model allows to foresee the occurrence of problems in the assembly and to identify their causes before making a tooling or real parts.

The Tecnomatix Quality Management system is also used to create complex measurement programs on the CMM and CNC machines, to analyze the measurement results based on a comparison with the tolerances assigned by the designer. Creation of measurement programs and analysis of results is carried out in the CAD environment on a mathematical model of a part including nominal geometry and assigned tolerances. This helps to examine the tolerances given by the designer on the part and the assembly, to identify critical design elements and to interpret the measurement results.

The product Variation Analysis CAD allows you to analyze the design in terms of the collection of products from parts with deviations, calculate the statistical characteristics of the deviations of the assembly and identify the tolerances with the greatest influence on the measured size. Using this tool allows you to manage the geometric accuracy in the scale of the company and take into account the real tolerance fields provided by the available equipment.

CMM Inspection Programming is designed to create measurement programs in a CAD environment. The approach realized in the product allows to unload the coordinate measuring machines (due to the exclusion of manual programming) and to ensure the high quality of the program due to the preliminary analysis of the collisions of the measuring head with the part and measuring equipment, optimization of the trajectory and the order of measuring the points of the surface and the optimal choice of the probe.

CMM Inspection Execution works directly on the controller’s workplace and allows you to perform part measurements in automatic mode and perform a primary part analysis, comparing the measured data with the tolerances specified by the designer. The results of the comparison can be obtained in a custom HTML format directly on the controller’s workstation. Since the original measurement program is presented in a machine-independent DMIS format, it is possible to perform measurements and analysis on a single program on different CMM models, which eliminates the ambiguity of the results of the control and eliminates the need to prepare separate programs for each CMM.

The measurement data stored in the Tecnomatix Quality Management environment can be displayed graphically, analyzed and transmitted within the enterprise. Engineered reports can contain measurement protocols, three-dimensional geometry, views, sections and text notes.

If you need this full soft, click download sysmbol and check out a bits to support this website. The link with all crack files + instruction for installation will appeare automatically after.

ANy comments, contact admin for more questions: clickdown.org@gmail.com

Thanks all of you. Goodluck