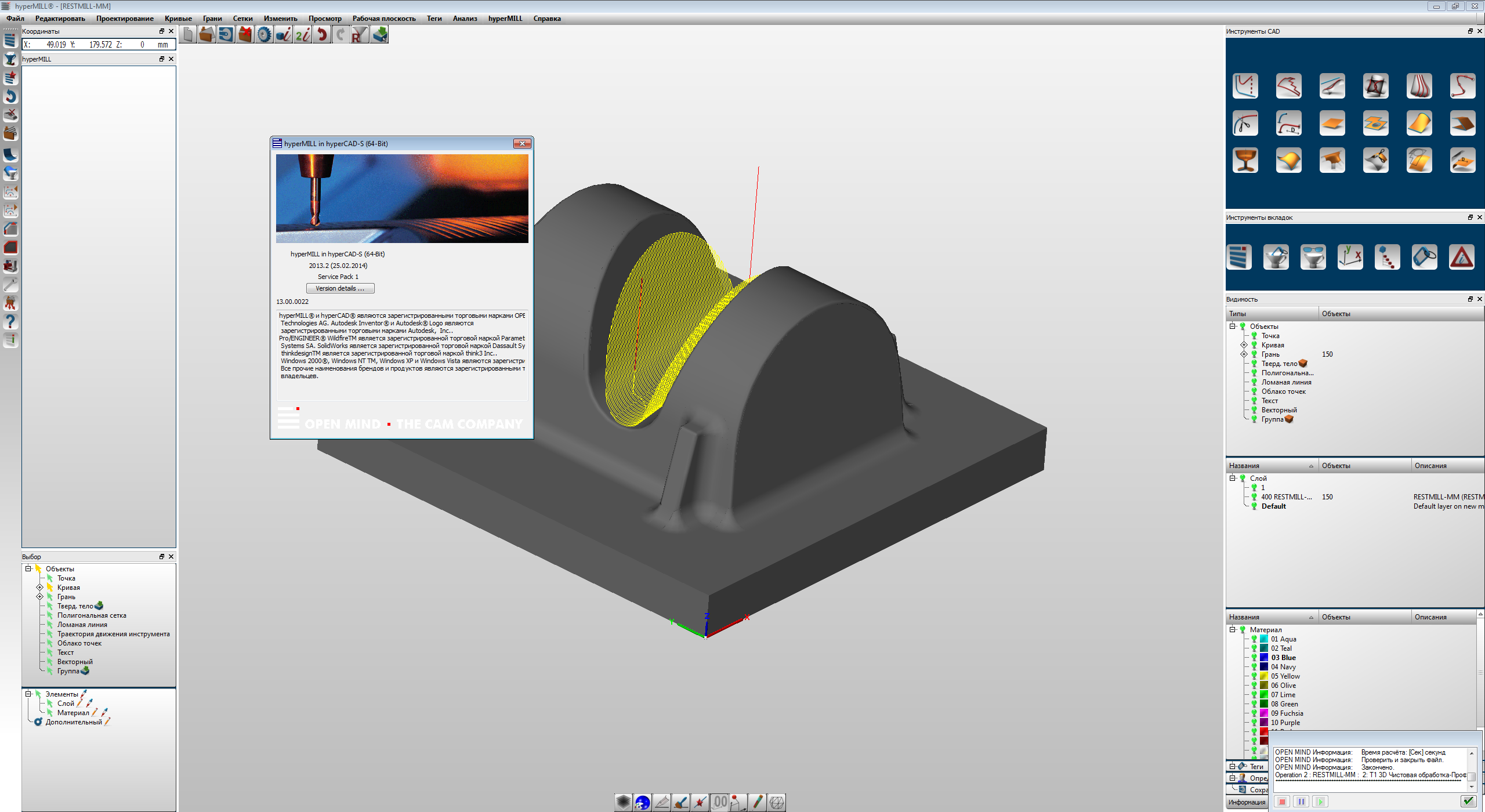

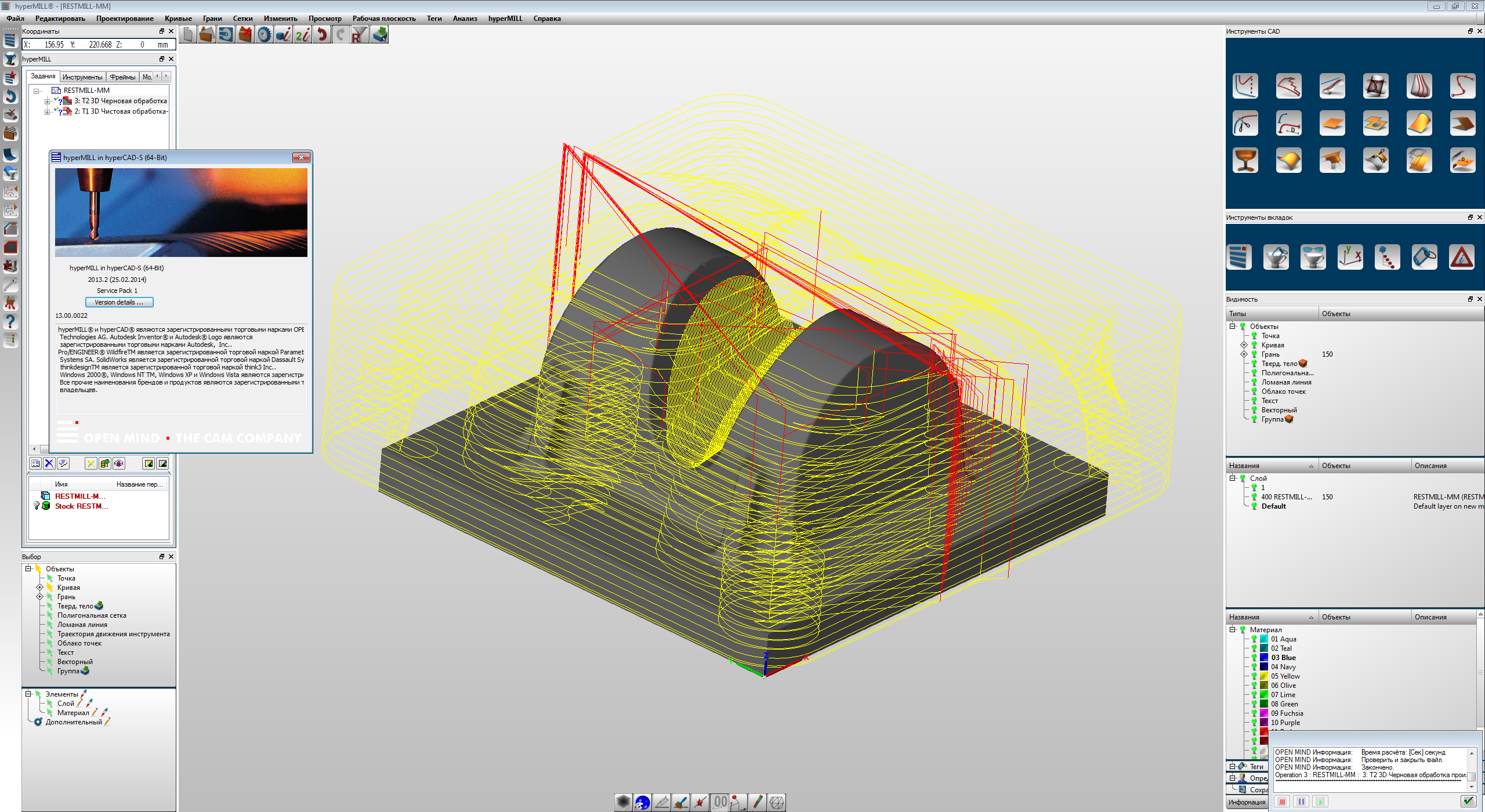

download hyperMILL 2013.2 SP1 x86+x64 | hyperMILL 2013.2 SP1 full crack

hyperMILL 2013.2 SP1 x86x64 full software

hyperMILL 2013.2 SP1 x86x64 tools path

machining with hyperMILL 2013.2 SP1 x86x64

Supported CAD Platforms: hyperCAD-S 2013.2 ( 64-Bit); hyperCAD 2009.3 (32-Bit); Inventor 2011 (32/64-Bit), 2012 (32/64-Bit), 2013 (32/64-Bit), 2014 (32/64-Bit); SolidWorks 2010 (32/64-Bit), 2011 (32/64-Bit), 2012 (32/64-Bit), 2013 (32/64-Bit), 2014 (32/64-Bit); TthinkDesign 2009.3 (32-Bit), 2011 (32-Bit), 2012 (32-Bit), 2013.1 (32 Bit-) the Supported the NC the Interfaces: VERICUT from the Version 7.0; NCSIMUL from Version 8.9

Description :

hyperMILL allows you to program both simple and complex geometry. With a variety of strategies for handling possible complete machining of parts without changing tools. In addition, hyperMILL provides many other opportunities for automation software, allowing to reduce processing time and optimize processes. These include technology fitcherov and macros, automatic functions, such as a function of reflection and transformation, job binding function and mode of production that reduce the time spent on ancillary operations, as well as the automatic validation and exception collisions.

hyperMILL 2D

This component is suitable for 2D common tasks. Its unique feature is that, in some cases, milling pockets and holes produced with the support of management cycles and intelligent features of machine tools.

hyperMILL Classic

This component is suitable for 2D- common tasks-and 3D-processing and provides the user with ample opportunity for effective programming. The app includes optimization features that allow you to perform the processing based on user requirements.

hyperMILL Expert

This component is used for complex tasks 2D- and 3D-processing and for high-speed processing and processing of hard metals. It includes standard and special machining strategies, as well as a large number of optimization functions that enable you to set processing operation based on the task and user requirements.

hyperMILL 5AXIS

Machining complex geometries with deep cavities, high steep walls and undercuts requires multiple changes in the installation tool in limited areas of milling. This can be achieved by using 5-axis machining and collision avoidance mechanism. Depending on the geometry and kinematics of the machine, you can choose 5-axis machining with a fixed position, automatic indexing or true simultaneous processing.

hyperMILL Special Applications

Processing geometries such as the impeller, Blisk, turbine blade, shaped channels and tires, has some special features, so the use of standard policies do not give the desired result. For these tasks hyperMILL offers special applications, integrated into the CAM system.

hyperMILL millTURN

Using this component, you can create NC programs for complete machining using a lathe and milling operations. Thanks to the full integration of the module into the development environment, you can use the database tools, workpiece support technology and collision checking mechanism in all operations of milling and turning. For all turning and milling post-processing tasks performed using a postprocessor.

hyperMILL Postprocessors

Since there is a wide variety of control systems and machines, as each product makes their processing requirements, the best solution in this case – it postprocessors, tailored to the specific conditions and challenges. Therefore, the company OPEN MIND Technologies AG develops its own postprocessors for its customers. Since postprocessors by OPEN MIND, are part of the respective CAM environment, they are significantly higher than those of standard solutions in concepts such as performance and security. Through this approach, the company can offer OPEN MIND postprocessors for any operations 2D-, 3D-, 5-axis and turning.

Advantages:

– Simple and efficient programming thanks to the automated functions, such as a function of reflection and transformation

– Intelligent functions, such as binding targets or mode of production, which can reduce the time spent on ancillary operations

– Automatic indexing of five-axis machining, which allows to optimize the processing time and reduce the load on the machine

– Number of five-axis machining strategies for cavities and surfaces

– collision monitoring and automatic collision avoidance to ensure maximum safety of the process

– the high-speed milling and high-performance roughing

– 2D-, 3D-, HSC-, and 5-axis milling and turning strategy, united in a common graphical interface

– The most advanced five-axis technology

– Full integration with special applications hyperMILL

– postprocessor for turning and milling strategies

IF YOU WANT TO DOWNLOAD THIS SOFTWARE, PLEASE CLICK TO DOWNLOAD BELOW.

FOR ANY PROBLEM, PLEASE CONTACT TO ADMIN: HADES@CLICKDOWN.ORG

WE WILL SUPPORT YOU AS SOON AS POSSIBLE.

THANKS

P/S: If you don’t know how to download, please refer to this link for your instruction: CLICK HERE