download VisualCAM 1.0 32bit 64bit full license 100% working

link download VisualCAM 1.0 win32 win64 full crack working forever

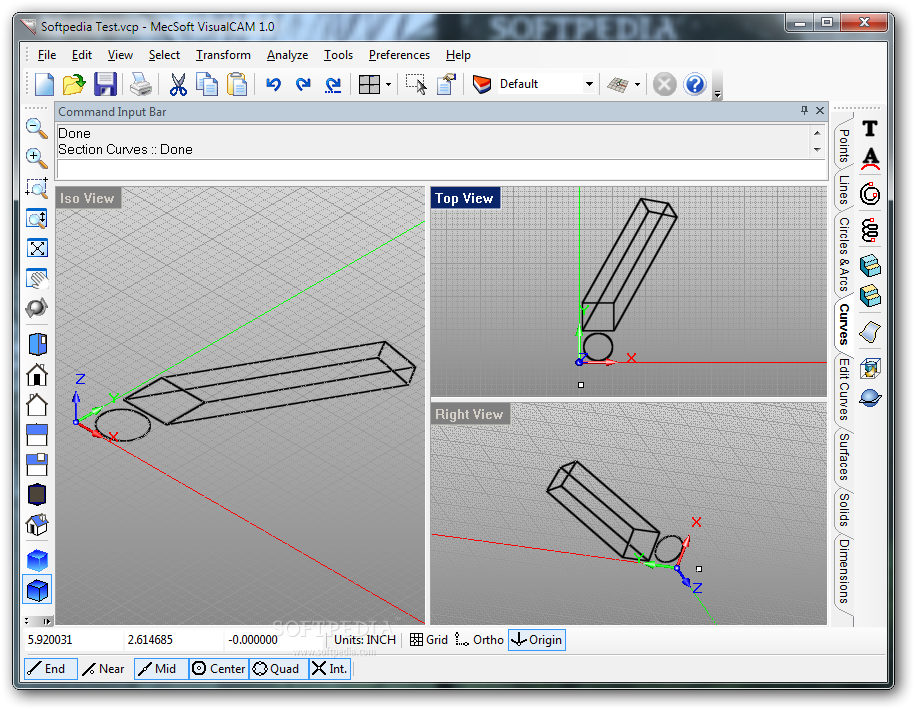

Working with VisualCAM 1.0 full crack

Interface language: English only

Description: Visual Mill is a modern software package that includes tools for generating control programs of three-, four- and five-axis milling machines, as well as visualization of the processing process with imitation of material removal. The system has the best in its class indicators for the ratio of “price / performance”, has a very simple and convenient interface.

The software package has its own modules for forming contours and surfaces, and also offers a very extensive list of imported formats and CAD-systems, the geometry of which can be transferred to Visual Mill. As “suppliers” of 3D models, Unigraphics, SolidWorks, Solid Edge, Autodesk Inventor, Mechanical Desktop, AutoCAD, 3D Studio, or any other system capable of forming an IGES file or model in STL format can act. Direct reading of DXF / DWG, Parasolid, SolidWorks and Solid Edge formats is provided.

The current version supports full-featured 2.5D and 3D milling, four-coordinate processing in conventional and multi-position (with discrete change of rotation angle) mode, as well as five-coordinate multi-position processing.

The geometry building tools allow you to describe the geometry of a part being processed using standard primitives (points, arcs, lines, curves, surfaces of various types). The system automatically generates contours of text lines on TrueType fonts, which simplifies their engraving.

The process of developing the program for the machine greatly accelerates the special types of processing:

Refinement of the same geometry with a tool of smaller diameter;

The possibility of combining roughing and finishing in one operation;

Milling of holes and threads, including using special cutters;

Selection of a set of holes for processing by the following criteria: minimum and maximum radius, position on a certain plane.

Visual Mill offers a wide range of tools, from a conventional end or spherical cutter to countersinks, countersinks, a threading tool and a shaped tool. A wide range of strategies for roughing, semi-finishing and finishing processing provides an opportunity to optimize the construction of the technological process. In the range of tasks solved with the help of Visual Mill, in addition to milling, virtually all types of machining are included: deep drilling, tapping and boring. The information for each process operation (processing area, tool description, feed values, material removal strategy) is stored, it is available at any time for editing and recounting the control program.

Visualization of the trajectory of moving the cutting tool in “wire” and halftone mode can be performed in the frame-by-frame representation on the part model or with the simulation of the material removal process. At the end of the visualization, it is possible to compare the result of the processing with the original model, while obtaining a graphical representation of the degree of error committed. During simulation, you can monitor the position of the tool and its holder, and, accordingly, prevent the collision of the holder with the workpiece.

The calculation of the time required for each technological operation allows, at the stage of creating the control program, to determine the processing time of the part as a whole.

Using the toolpath trajectory editor, you can optimize the control file, and also multiply the trajectory with an array or get its mirror image, which reduces the processing time and allows the most efficient use of the capabilities of CNC machines. The generator of postprocessors of the program Visual Mill provides preparation of control programs for machine tools of domestic and foreign production.

A list of the main features of Visual Mill

Tools for creating / editing geometry

Creation of two-dimensional (contours) and three-dimensional (surface) geometry.

Support for layers.

Multiple undo / redo commands.

Use the clipboard (Clipboard).

Support for text using True Type fonts.

Milling 2.5 coordinates

Processing of pockets.

Processing along contours (profiles).

Engraving.

Processing closed loops (space bounded by a contour).

Refinement using a tool of smaller diameter.

V-shaped treatment.

Milling holes.

Thread cutting with a milling cutter.

Additional options for processing pockets and profiles.

Three-axis milling

Horizontal pre-treatment.

Parallel finishing.

Horizontal finishing.

Preliminary processing by drilling by contour.

Horizontal refinement using a tool of smaller diameter.

Finishing by drilling by contour using a tool of smaller diameter.

Three-dimensional processing of pockets (milling on the surface of the bottom of the pocket).

Pencil processing.

Processing the remainder.

Processing of vertical and horizontal steps.

Processing along a curve.

Spiral processing.

Radial treatment.

Equidistant processing between two curves.

Reverse prototyping – the reconstruction of the trajectory according to the text of the control program for the machine.

Four-axis milling

Four-coordinate multi-position processing.

Four-coordinate pre-treatment.

Four-coordinate finishing.

Four-coordinate engraving.

Five-axis milling

Five-axis multi-position processing.

Hole processing

Automatic selection of holes, sorting.

Drilling.

Thread cutting.

Boring.

Reverse boring.

Specify custom cycles.

Simulation of the cutting process

Animation of tool motion along a path.

Simulation of material removal.

Improved method of simulating the cutting process.

Description of tools

Support threading cutters.

Simulation of holders.

Shaped tool.

Tools for editing the trajectory

Graphical editing of the trajectory.

Arrays, mirror reflection and rotation of the trajectory.

Optimization of the trajectory.

Postprocessor Generator

Configurable postprocessor generator.

Support for the fifth coordinate in the postprocessor.

User-defined loops.

Support for spiral and screw approximations.

Simulation of cycles.

DNC functions

Data transmission / reception and control of the rack machine from the computer.

If you want to download VisualCAM 1.0 full license, please click to DOWNLOAD symbol and complete check out a little help my website is maintained. The download link is appeared automatically when you complete check out.

Please see youtube video for download instruction by open *.txt file and copy youtube video link paste to your browser If you don’t know how to download.

Inside folder VisualCAM 1.0, already have crack’s file and instruction how to install this VisualCAM 1.0 step by step. I guarantee you can install VisualCAM 1.0 successfully if you follow that instruction.

If you also can not install it or any problems, please contact to me by email: clickdown.org@gmail.com, then I will help you to install software by teamviewer.

Thanks a lot