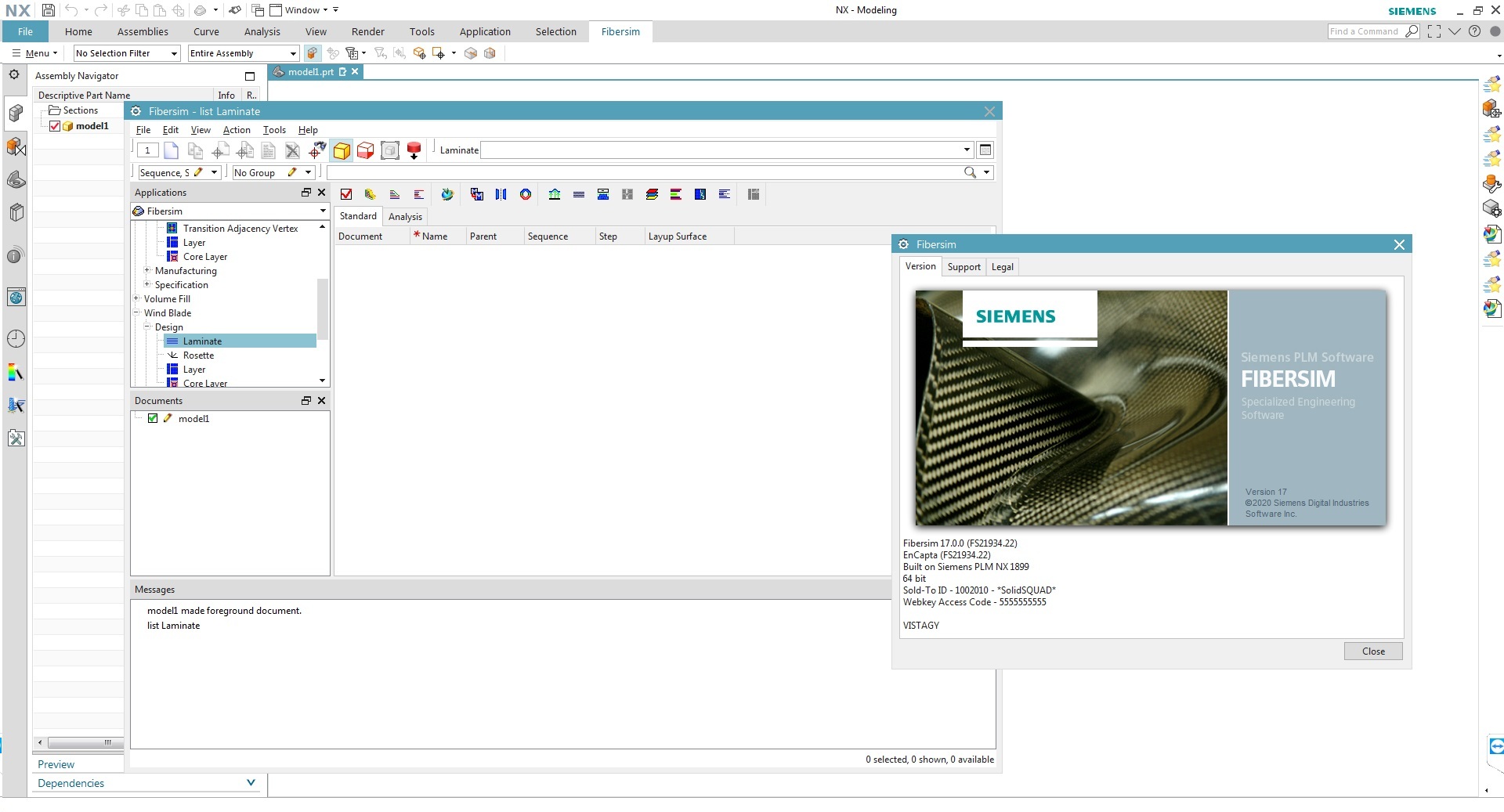

Download Siemens FiberSIM 17.0.0 for Catia V5-Creo-NX x64 full license

Link download Siemens FiberSIM 17.0.0 for Catia V5-Creo-NX win64 full crack

Working with Siemens FiberSIM 17.0.0 for NX full crack

Working with Siemens FiberSIM 17.0.0 for Creo full license

Working with Siemens FiberSIM 17.0.0 for catia v5 full license

Systems: Win 7 / 8.1 / 10 64bit

Language: English

System requirements

For Fibersim 17.0.0 for CATIA V5

CATIA V5 R26-R29 64-bit

For Fibersim 17.0.0 for CREO Parametric

Creo Parametric 4.0

Creo Parametric 5.0

Creo Parametric 6.0

For Fibersim 17.0.0 for Siemens NX

NX-11.0.1 + 64-bit

NX-12.0.1 + 64-bit (to use NX-12 the minimum supported version is NX-12.0.1)

NX-1847 Series 64-bit (1847-1867)

NX-1872 Series 64-bit (1872-1892)

NX-1899 Series 64-bit (1899-1919)

Description: FiberSIM from Siemens PLM Software allows specialists in the aerospace, automotive and wind energy industries to optimize the weight, cost and performance of PCM products (polymer composite materials) by accurately controlling the orientation of the reinforcing fibers.

The use of Fibersim reduces risk by optimizing the design and manufacturing process of durable and lightweight innovative structures in the aerospace, automotive and wind energy industries. The package was developed by Vistagy, acquired by Siemens on December 7, 2011 and is a commercial division of Siemens PLM Software.

Fibersim reduces the degree of uncertainty in the behavior of composite parts under loads by describing, transmitting, and verifying the required fiber orientation throughout the product development process, ensuring exact compliance with specified technical specifications. Using convenient tools that eliminate errors when working with project data, you can reduce the risk of designing complex parts with excess weight, uncertain properties and overpriced.

Fibersim is an advanced PCM product development solution that helps world leaders in aerospace, automotive, wind and other industries successfully solve complex problems throughout the entire production cycle – from conceptual design development, detailed design, layer modeling and production data creation to quality control . Fibersim can be fully integrated into market-leading commercial 3D CAD systems.

Fibersim Benefits:

•

Advanced optimization at the design stage

Fibersim helps to reduce the degree of uncertainty in the behavior of PCM products under stresses thanks to the new Spine-Based Rosette Coordinate System, which makes it possible to simulate stacking of materials with an orientation along the path. This information can be transferred between all participants in the development process throughout the cycle. Ensuring the necessary orientation of the fiber of the manufactured parts — whether it be an aircraft-stringer, a car frame, or a 60-meter blade of a wind turbine — is a critical factor in optimizing the weight and performance of a product.

•

Accurate modeling of composite materials on complex shapes

The Fibersim package was the first to feature advanced process modeling for multilayer materials, including multiaxial fabrics. These functions form the basis of Fibersim, which allows you to simulate even more materials and production processes using the first-ever function of Spine-Based Simulation for parts with longitudinal bending. The material laid along the generatrix of such parts as an aircraft stringer, a car body pillar or a guide blade of a wind turbine will have local waviness and deformation. Determining the causes of these phenomena at an early stage of the production cycle allows you to make the right key decisions for the timely and cost-effective provision of the expected strength of the parts.

•

Effective transfer of a full description of the part between the departments of design and calculation

The program presents a new functionality for the exchange of descriptions of multiaxial fabrics and fillers. This functionality provides the opportunity for effective interaction between designers and engineers, taking into account the most important components throughout the product development cycle. For an accurate calculation of the rigidity and strength of parts, it is necessary to take into account the specific characteristics of multiaxial fabrics and fillers, which are often used in designing in the aerospace, automotive and wind energy industries.

•

Simplification of the development of composite parts and documentation

Fibersim helps simplify the process of developing composite parts with the help of new, easy-to-use design tools and documentation generation, created for engineers with different experience in the field of RMB. The most difficult and time-consuming task in the design process is to work with the specifications of the run between zones of constant thickness. The Fibersim package introduces for the first time the Visual Stagger Editor feature to simplify working with such specifications. Large aerospace panels, such as wings, stabilizers or tail units, have a significant number of different run profiles. The run profile editor facilitates profile development and reduces the likelihood of design errors.

If you want to download Siemens FiberSIM 17.0.0 for Catia V5-Creo-NX full license, please click to DOWNLOAD symbol and complete check out a little help my website is maintained. The download link is appeared automatically when you complete check out.

Please see youtube video for download instruction by open *.txt file and copy youtube video link paste to your browser If you don’t know how to download.

Inside folder Siemens FiberSIM 17.0.0 for Catia V5-Creo-NX, already have crack’s file and instruction how to install Siemens FiberSIM 17.0.0 for Catia V5-Creo-NX step by step. I guarantee you can install Siemens FiberSIM 17.0.0 for Catia V5-Creo-NX successfully if you follow that instruction.

If you also can not install it or any problems, please contact to me by email: [email protected], then I will help you to install software by teamviewer.

Thanks a lot