Download Simufact Joining Optimizer 2025.2 x64 full license

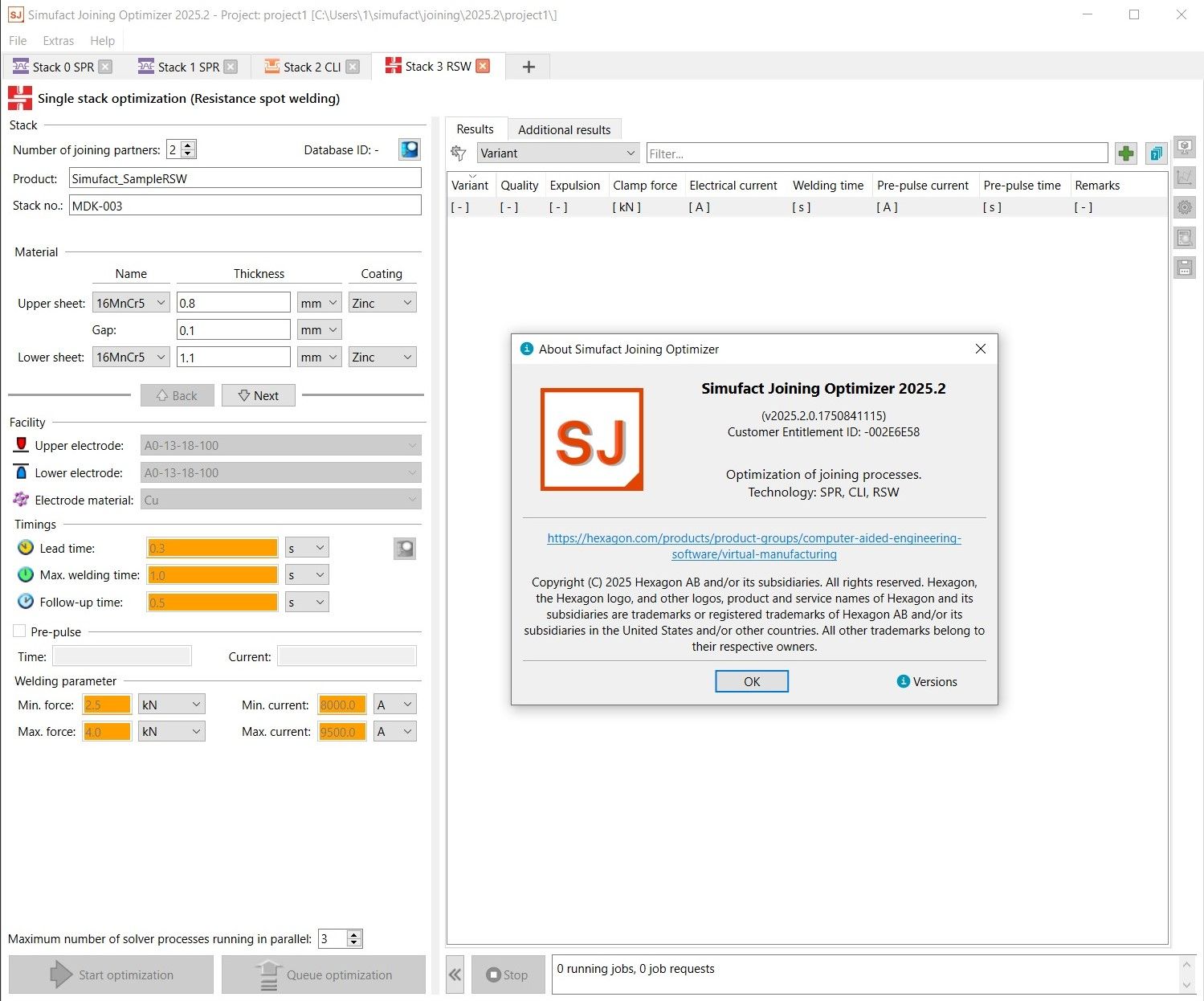

Simufact Joining Optimizer 2025.2 – Intelligent Joining Process Design & Optimization

Download Simufact Joining Optimizer 2025.2 x64 full license

Link download Simufact Joining Optimizer 2025.2 win64 full activated

Description of Simufact Joining Optimizer 2025.2

Simufact Joining Optimizer 2025.2 is an advanced engineering solution designed to optimize mechanical joining processes such as self-piercing riveting, clinching, and other fastening techniques. Developed by Hexagon Manufacturing Intelligence, this software helps engineers determine optimal joint configurations, improve structural performance, and reduce manufacturing costs without extensive physical testing.

The 2025.2 release enhances optimization algorithms, expands material compatibility options, and improves workflow efficiency, making it an essential tool for lightweight design and modern multi-material assemblies.

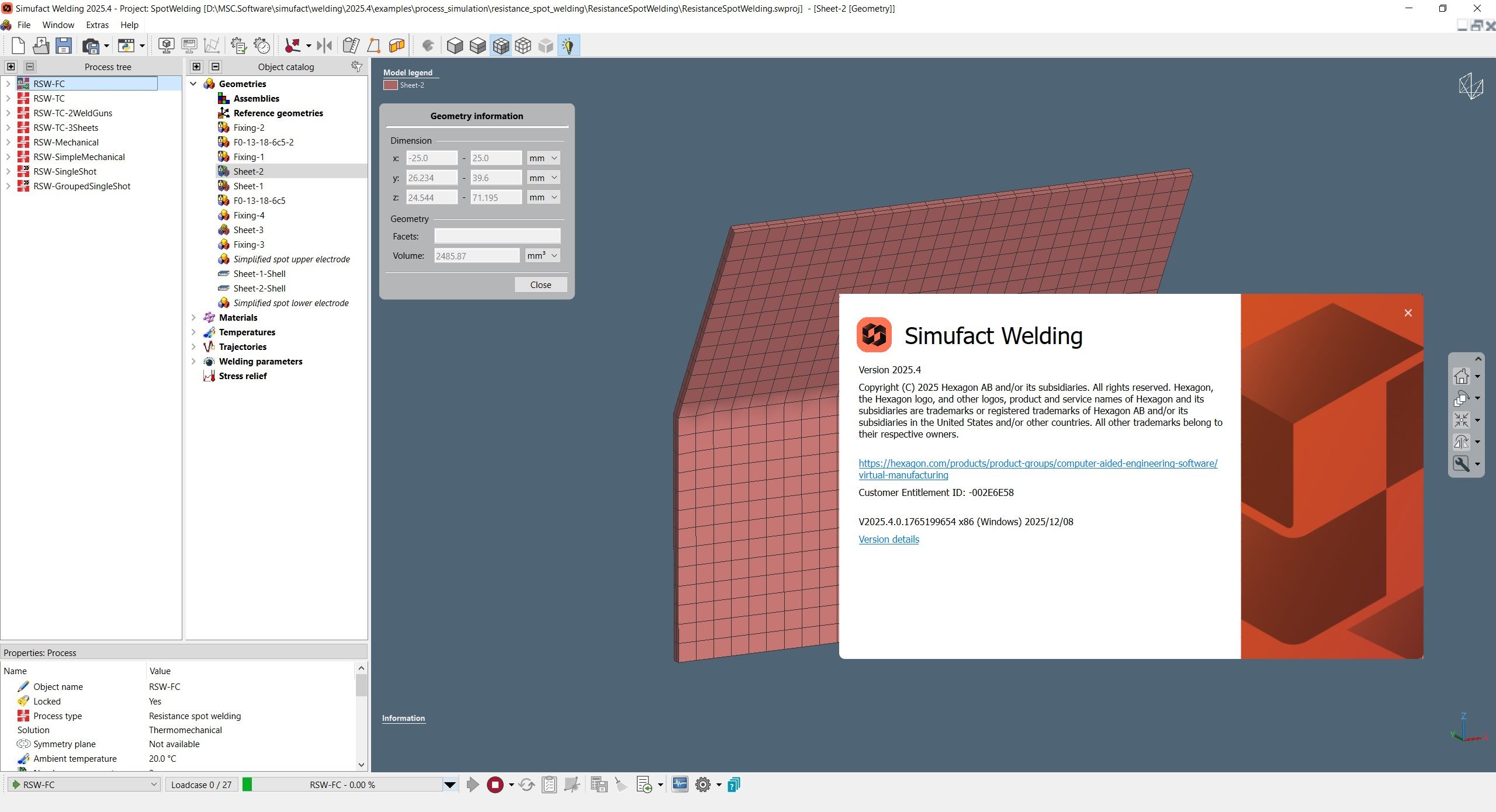

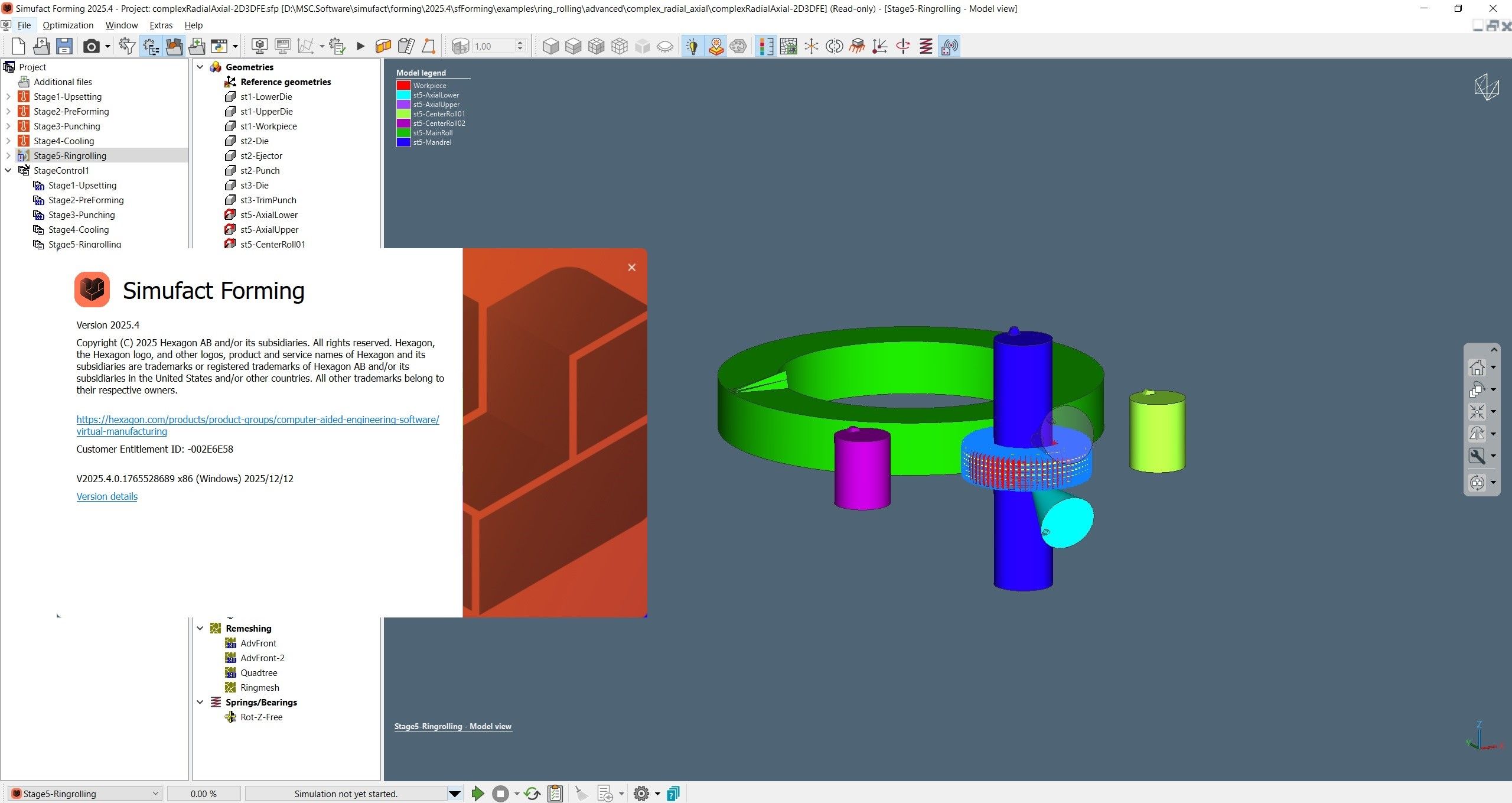

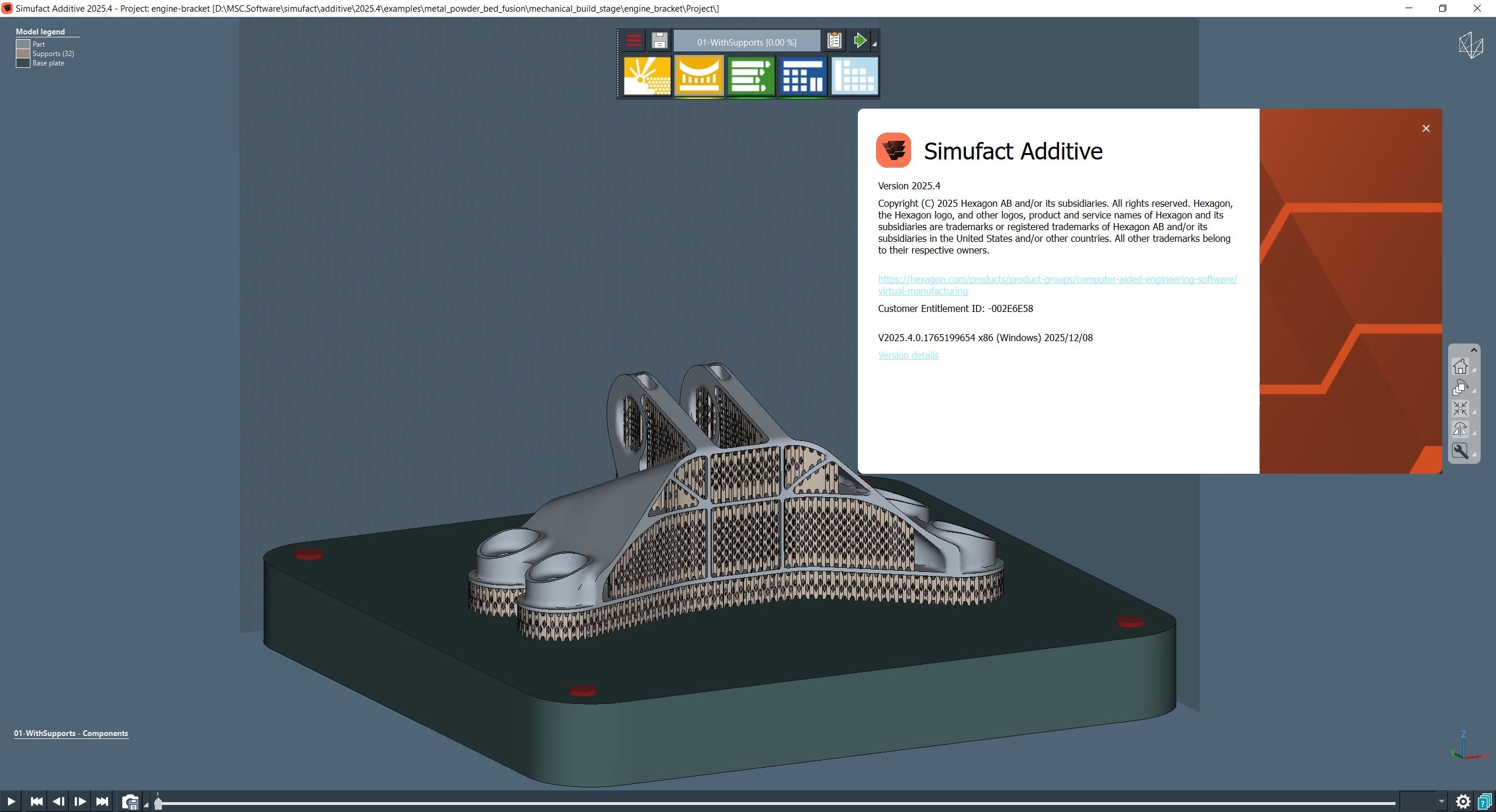

Simufact Joining Optimizer provides a virtual engineering environment for evaluating and optimizing joining techniques used in automotive body structures, aerospace components, and industrial assemblies. Engineers can analyze joint strength, failure behavior, and material interactions to ensure durability and performance.

Version 2025.2 focuses on improved prediction accuracy and streamlined optimization processes, supporting advanced materials such as aluminum alloys, high-strength steels, and mixed-material stacks.

Features of Simufact Joining Optimizer 2025.2

🔹 Automated Joint Optimization

Intelligent determination of optimal rivet or clinch configurations

Automatic parameter optimization for strength and durability

Reduced trial-and-error testing

🔹 Multi-Material Compatibility

Supports aluminum, high-strength steel, composites, and mixed stacks

Accurate modeling of dissimilar material joining behavior

Ideal for lightweight and hybrid structures

🔹 Strength & Failure Prediction

Evaluate joint strength and load-bearing capacity

Predict failure modes and fatigue performance

Improve long-term durability and safety

🔹 Self-Piercing Riveting & Clinching Analysis

Simulation and optimization of self-piercing riveting (SPR)

Clinching process evaluation and improvement

Ensure consistent joint quality

🔹 Lightweight Design Support

Optimize joining strategies for weight reduction

Improve structural stiffness and crash performance

Support sustainability and efficiency goals

🔹 Performance & Algorithm Enhancements

Faster optimization routines and improved solver efficiency

Enhanced accuracy for complex material stacks

Efficient handling of large joint datasets

🔹 Workflow Integration & Automation

Seamless integration into digital engineering workflows

Batch processing for large assembly evaluations

Supports design iteration and rapid decision-making

🔹 Visualization & Reporting Tools

Clear joint performance visualization

Automated reporting for engineering validation

Easy comparison of optimization scenarios

Benefits

Reduce development time and physical prototyping

Improve joint strength and structural reliability

Optimize joining processes for multi-material assemblies

Lower manufacturing costs and improve efficiency

Support lightweight design and sustainability initiatives

Typical Applications

Automotive body-in-white assembly

Aerospace structural joints

Electric vehicle battery enclosures

Consumer electronics and appliance manufacturing

Industrial equipment and lightweight structures

Conclusion

Simufact Joining Optimizer 2025.2 provides powerful optimization capabilities for modern joining technologies. With advanced strength prediction, multi-material support, and intelligent optimization tools, it enables manufacturers to create stronger, lighter, and more efficient assemblies while reducing production costs and development time.

If you want to download Simufact Joining Optimizer 2025.2 full license, please click to DOWNLOAD button to download.

Inside package Simufact Joining Optimizer 2025.2, already have cracked files and instruction how to install Simufact Joining Optimizer 2025.2 step by step. I guarantee you can install Simufact Joining Optimizer 2025.2 successfully if you follow that instruction.

If you also can’t install it or get any problems, please contact to me by email: [email protected], then I will help you to install software by teamviewer or Ultraviewer or Anydesk.

Thanks a lot