download Vero VISI v2016 R1 | link Vero VISI v2016 32bit 64bit full

Link Vero VISI v2016 R1 win32 win64 full license 100% working

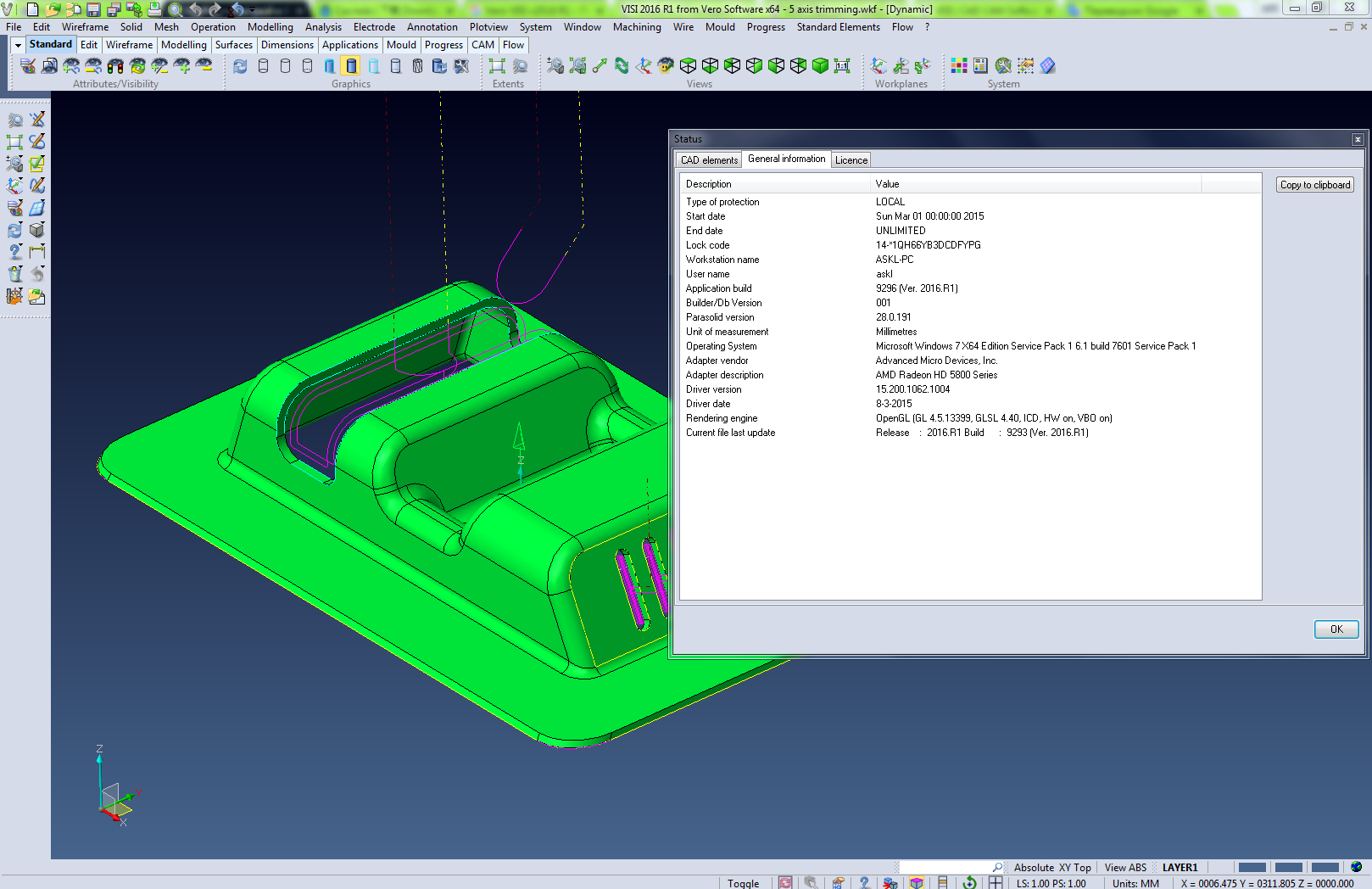

Machining with Vero VISI v2016 R1

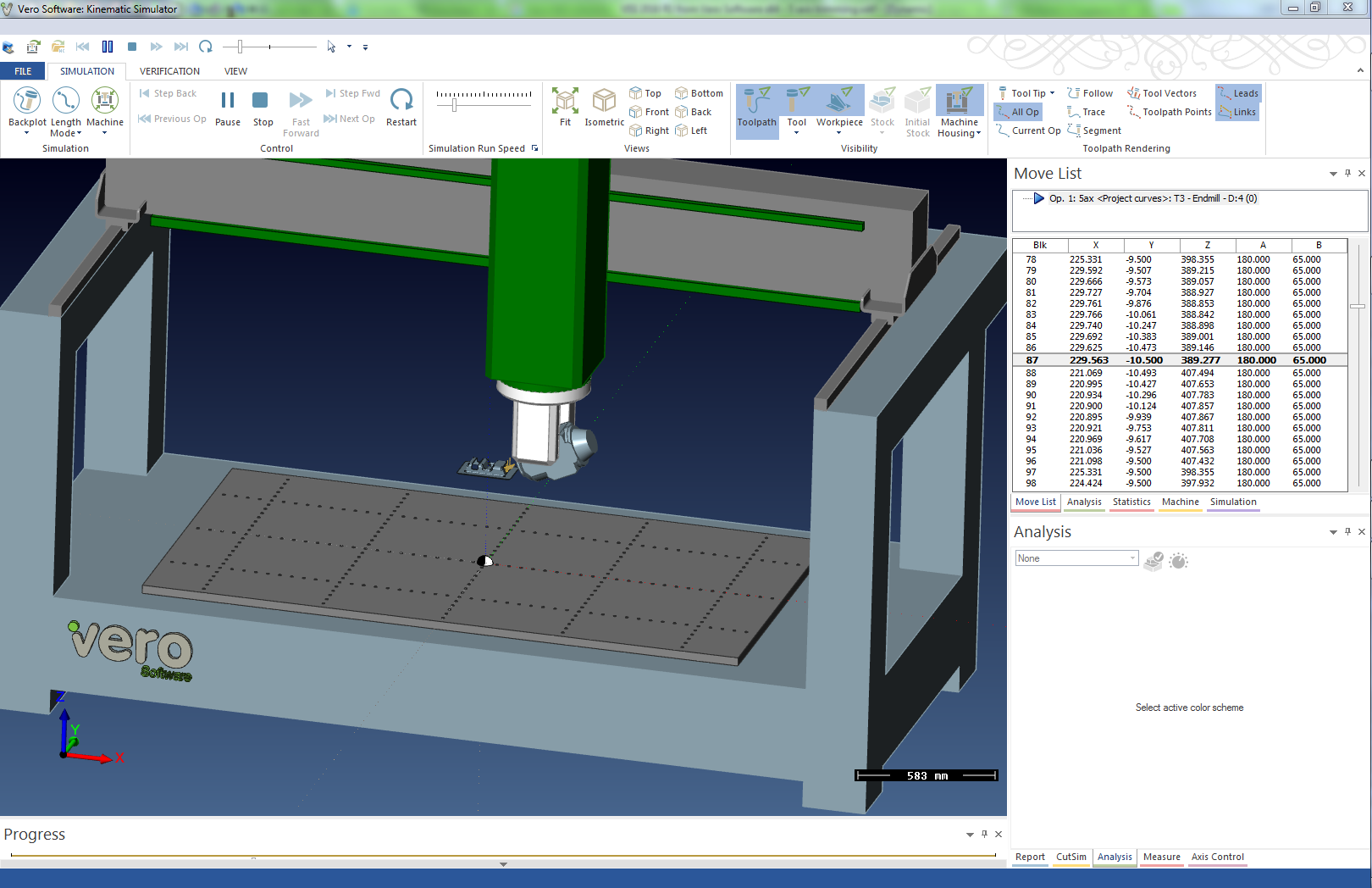

Simulation with Vero VISI v2016 R1

Description: VISI – one of the world’s leading CAD / CAM solutions for the manufacture of molds, dies and other tooling.

VISI Technologies combine wireframe, surface and solid modeling with a clear strategy planar, three-dimensional and 5-axis machining with special high-speed mode.

Specific modules for the construction of molds for various kinds of casting material flow analysis and progressive dies with incremental scanning make it possible to achieve a previously unattainable level of productivity ..

Vero Software offers dedicated solutions that no longer need to switch between programs from different manufacturers and run conversion solid geometry to the surface required with traditional IT systems.

VISI provides software solutions for the following manufacturing operations:

VISI Modelling- foundation of all VISI suite of products, powerful system for solid and surface modeling, created on the basis Parasolid® kernel, which is considered the industry standard. Together with poverhnosteyVero processing technology, analysis models and 2D-designing, VISI Modelling package gives you the opportunity to design, edit, and edit the most complex 3D-objects.

VISI Analysis- Checking and preparation of model geometry. When working with imported data is an important quality of the model. Finding potential problems at an early stage of the project will greatly simplify the task of the designer and will allow in the future to save a lot of time as we develop.

VISI Mould- specialized solutions for mold design, taking into account features of the equipment used in this industry. With it, the user passes the entire design process, in real time watching how the changes affect the finished product mold design.

VISI Flow- All steps for creating molds can enjoy the benefits of this solution, which allows to optimize the design and customize the casting parameters. The creators of the finished products, mold and foundry also benefit from Vero Software innovative technologies for casting simulation, allowing to create a reliable and cost-effective mold with optimal casting conditions. Module VISI Flow – a unique tool for forecasting and analysis of pre- and post-production with a consistent engineering design of molded plastic products.

VISI Electrode- automated module for the development and management of electrodes and their holders for processing hard to reach areas of molds and dies. Convenient design holders, simulation and collision avoidance ensure correct operation of the electrode on the first try.

Construction VISI Progress- successive dies. Specific to the industry specific features help more efficiently and effectively design a snap. Intelligent solutions VISI Progress, to help the designer, reduce errors and significantly improve the efficiency of production.

VISI Multi-Slides- Construction camshafts for transfer press. Expansion module VISI Progress for the construction cam shafts used in the transfer press specially for bending. With it, there is a fast and efficient simulation and synchronization of the bending cycle, the next phase of the sequential cutting stamp. Construction of the cam shafts and the desired dimensioning is done automatically for each of the presses.

VISI Machining 2D- simple, practical and intuitive solution for processing various operations, including 4- and 5-axis. Intelligent recognition on the grounds that automatically selects the form for processing directly on the solid geometry and create reliable toolpaths for milling and drilling.

VISI Machining 3D- Creates intelligent processing path for the most complex 3D-parts. Special high-speed milling techniques and built-in smoothing algorithms create high quality NC-Code. These intelligent toolpaths reduce cycle time and improve production efficiency.

VISI Machining 5 Axis- 5-axis machining has traditionally been considered the most suitable for automotive and aeronautical. It has many advantages also apply to the production of molds and dies. Module VISI Machining – productive solution for creating high-performance cutting tool paths with a powerful anti-collision function for even the most complex three-dimensional models.

VISI PEPS-Wire- leader in its field, the system will create control programs for wire erosion PEPS Wire EDM, designed specifically for precision technology, production equipment, molds and dies as part of VISI complex. VISI PEPS-Wire provides automatic recognition of wire shapes, including conical, and 4-axis directly from solid geometry. Products of various shapes easily handled reliable paths of wire erosion and CNC-tested code, suitable for any kind of erosion of equipment.

VISI Blank- integrated solution for creating slabs of the complex of 3D-models. Especially useful it is to create a sheet metal blanks, blanks for the production of successive stamps, processing presses, and others. The main advantages of VISI Blank are in perfect integration with the popular package VISI Modelling based on the industry standard Parasolid kernel and proprietary Vero in surface modeling and planar design.

Click DOWNLOAD sysmbol to down this full software. The link will appeare after your check out.

Any questions, contact admin via email: clickdown.org@gmail.com

Thanks all